Food- and drink-processing industry

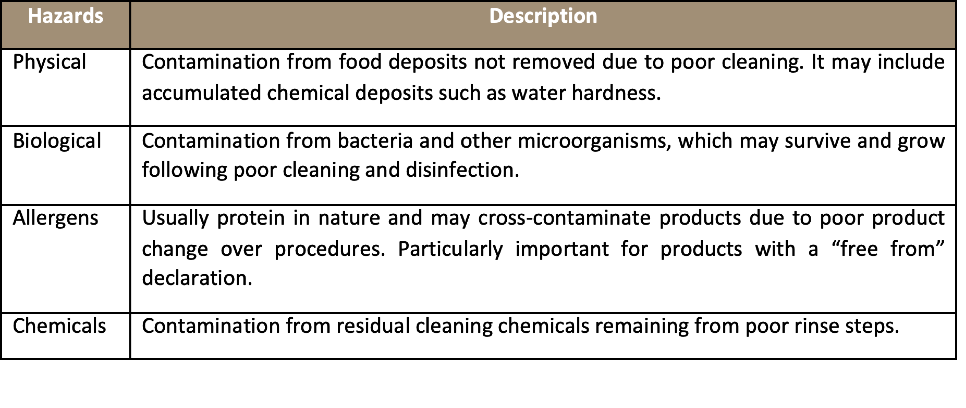

Cleaning and disinfection are critical within the food and beverage industries. This is essential in order to comply with legal and technical standards and ensure food hazards (Table 1) are controlled.

To provide a safe environment for the manufacture of food and beverages means that your plant and equipment should be able to produce food free of physical, allergenic, chemical and microbiological hazards. Cleaning and disinfection cost money, however, neglecting this step in this kind of industry, will lead to an increased number of indirect costs like lower productivity, complaints, restrictions and, ultimately, closing the business.

Cleaning is the complete removal of residues and soil from surfaces, leaving them visually clean. After cleaning, a disinfection is required, to effectively kill microorganisms so that their numbers are reduced to a level which is neither harmful to health nor to the quality of perishable goods. Without effective cleaning, disinfection will be compromised.

Freebac is the perfect disinfectant for the food and drinks industry, since the product line is approved by Norwegian Food Safety Authority (Mattilsynet), and it is manufactured from food safe ingredients; adding no taste, smell or colour with correct usage.

General Applications:

- Disinfection inside piping systems.

- Surface disinfection – walls and hard surfaces.

- Fog and misting systems.

- Disinfection of fruits and vegetables.

- CIP (Cleaning in Place).

- Disinfection of bottles.

Freebac Mucasol

Freebac Mucasol is a food safe formulation manufactured specifically to remove slime and fats from fish before processing.

Removal of the slime layer is essential for producing safe and high-quality fish products. Increased bacteria growth occurs if the slime layer remains on the fish, leading to consumer food-poisoning. Listeria monocytogenes is a common and dangerous bacterium that Freebac Mucasol can prevent. Usually removing slime from the fish is done mechanically. This can damage the fish, give an unappetizing appearance and potentially spread existing bacteria in the slime layer.

When using Freebac Mucasol, the process of de-sliming fish can be done fast and effective only with access to a water bath, or slow when the fish is in a cool storage. Removal of slime with Freebac Mucasol leads to better hygiene in the whole process area. The equipment used in the process will have less slime and pollution from bacteria.

Advantages:

- Removal of the slime layer without mechanical processing.

- Prevents Listeria monocytogenes.

- Can be used rapidly when the fish goes straight to processing, or slowly in a cold storage room with the product applied on the fish.

- Avoids mechanical de-sliming and thereby damage to the fish resulting in a better end product, and better plant hygiene.

- The fish will not be damaged in the de-sliming process and the product will not leave any odour, colour or taste.

- Consists of food grade ingredients, and does not affect the food safety.

- Sustainable, only degrades to oxygen and water.

Freebac Rind-Off

Freebac Rind-Off is specially designed to remove the rind (coating) off the cheese during production. The removal of cheese rind is essential for producing safe and high-quality cheeses products.

If the rind layer is not removed properly the product can become susceptible to bacterial growth during storage.

The traditional way to remove the rind off the cheese is to soak the cheese in hot water for weeks. Then, each cheese is flushed with hot water and stored. The disadvantages with that method is high energy consumption, with no guarantee that all the rind is removed. The cheese gets a rough surface and unnecessary amounts of proteins and fats gets flushed away in the process. It also creates a perfect place for bacterial growth if the water temperature is not carefully controlled.

Advantages:

- Easily removes the rind off the cheese.

- Water savings – uses less water than traditional methods of rind removal.

- The cheese gets an even surface.

- Prevents contamination of the cheese.

- Sustainable formulation which degrades to oxygen and water.

Hand & surface

Hand & surface Agriculture & livestock

Agriculture & livestock Restaurant & hotel services

Restaurant & hotel services Medical, dental & veterinary sectors

Medical, dental & veterinary sectors Schools, sports & other buildings

Schools, sports & other buildings Swimming pools and spas

Swimming pools and spas Aquaculture & fish industry

Aquaculture & fish industry Food & drinks processing industry

Food & drinks processing industry Water Treatment

Water Treatment